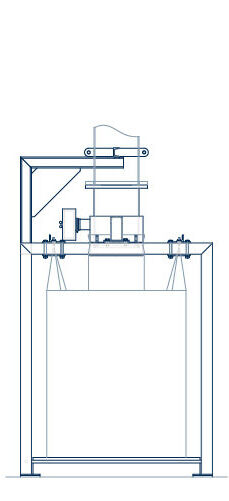

Big bag-Filling Systems

Our high-performance big bag filling systems are used inside the chemicals and plastics processing industries, the pharmaceutical and food processing industries, in power plants and in waste incineration plants. They are characterised by their reliable, easy mode of operation and a dust-free filling procedure. Depending on product characteristics and flow behaviour, we offer a selection of different systems and modular expansion options to ensure optimised material flow, efficiency and safety.

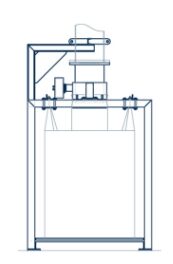

Type A Basis

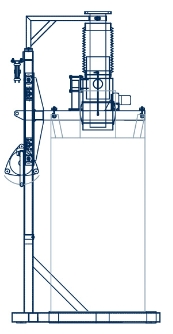

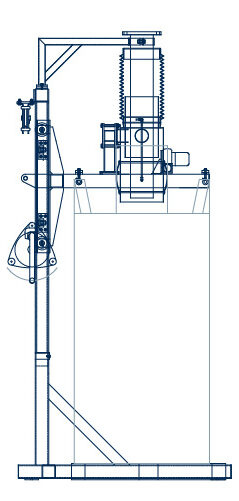

Type B Standard

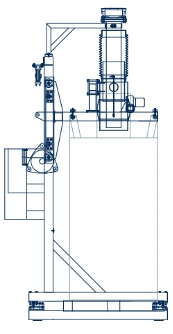

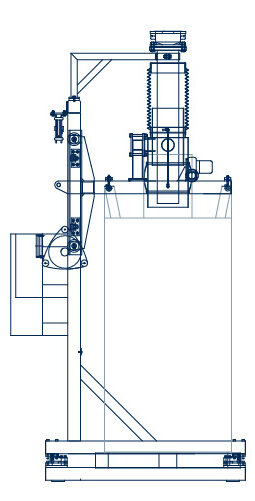

Type C Komfort

In process engineering, the focus is on operational safety and economic efficiency. Therefore, all variants of our Big Bag filling stations are based on a strictly modular design concept.

This gives you maximum flexibility in configuration and the ability to tailor an emptying station exactly to your needs.

We distinguish between the following systems:

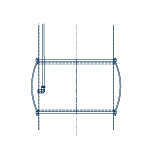

Inflatable clamp

Inflation unit

Weighing

Level-Indicator

Bag torque clamp

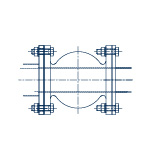

Type A Basis

Basic equipment:

■ For free-flowing or granular, dust-free and environmentally-friendly bulk materials

■ Base frame as welded construction with mechanical height adjustment

■ Filling head, incl. a lateral filter element for discharge of displaced air

■ Basic clamping unit

Type B Standard

Basic Equipment:

■ For all bulk materials, granular or fine-grained, good or poor flow, environmentally friendly or environmentally critical

■ Base frame in heavy welded steel construction

■ Filling head with:

1. Inflatable clamp for quick and safe connection of the

Big Bag Filler Neck

2. Inflation unit with a fan for a complete opening of the empty big bag

3. Lateral venting nozzle with a filter element or connection to an on-site dedusting system for discharging the dust-laden excess air

■ Manual height adjustment

■ Platform for proper operation with different

Big Bag sizes

Type C Komfort

Basic Equipment:

■ For all bulk materials, granular or fine-grained, good or poor flow, environmentally friendly or environmentally critical

■ Base frame in heavy welded steel construction

■ Filling head with:

1. Inflatable clamp for quick and safe connection of the

Big Bag Filler Neck

2. Inflation unit with a fan for a complete opening of the empty big bag

3. Lateral venting nozzle with a filter element or connection to an on-site dedusting system for discharging the dust-laden excess air

■ Manual height adjustment

■ Platform for proper operation with different

Big Bag sizes

Add-ons:

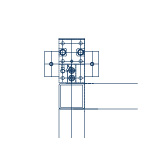

Inflatable clamp

This module serves to the quick and semi- automatic connection of the Big Bag filler neck, providing an optimal dust-tight seal.

After fitting the filler neck onto the units filling head and the inflatable clamp can be activated by the press of a button. Depending of the Big bags size and product volume flow, a filling rate of up to 30 Big Bags per hour can safely be achieved.

Big Bag Inflation unit

In order to achieve high filling rates it is necessary for the Big bag to be ready for use as quickly as possible. To ensure short cycle times the filling head can be equipped with a compact low-pressure fan which inflates the Bag safely and quickly .

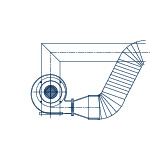

Lateral venting nozzle with pinch valve

The possibly dust-laden displacement air escaping during the filling process can be discharged via a connection pipe and a filter or the on-site dust removal system. The pinch valve is closed when the big bag is inflated so that the air cannot be discharged via the connection pipe. During the filling process, the pinch valve is then opened to allow the excess air to escape.

Weighing

To safely determine a filled in product weight, 3-4 load cells can be fitted to the bottom floor plate or to the fixing elements of the Big Bags wrist straps. According to the further requirement, the attained data can be locally displayed on an analysis unit, may be labelled with a printer or they can be passed onto an on-site SPS system. A calibrated weighing solution can also be supplied as an option.

Level indicator

To avoid an overfilling of Big Bags, a level indicator can be integrated into the Big Bag filling head. Together with a visual and/or acoustic display, or in combination with a top-side shut-off valve, the filling process can be safely monitored.

Bag torque clamp

Instead of a simple bag clamp, a bag torque clamp can be installed. This is used for easier fastening of the big bag infeed neck.